Sandblast Vs Soda Blaster: The Ultimate Showdown For Surface Cleaning

So, you're here because you're wondering which one's the real champ when it comes to cleaning surfaces—sandblasting or soda blasting? Let me tell you, this debate's been going on for years, and both sides have some serious pros and cons. If you're in the market for a surface restoration solution, you better buckle up, ‘cause we’re diving deep into the world of sandblast vs soda blaster. This isn’t just about picking tools; it’s about making the right decision for your project!

Now, before we get into the nitty-gritty, let’s establish one thing: both sandblasting and soda blasting are powerful methods for cleaning and prepping surfaces. But they’re not exactly the same, and that’s where the fun begins. Whether you're restoring a car, cleaning concrete, or prepping metal for painting, knowing the difference between sandblast vs soda blaster could save you time, money, and headaches. Stick around, and I’ll break it down for you step by step.

Think of this article as your guide to understanding the battle of the blasting methods. By the end, you’ll know exactly which one fits your needs. So, let’s not waste any more time and jump right into it, shall we?

Read also:Famous Peruvian People Exploring The Legends Who Made Peru Shine

Understanding Sandblasting: The Classic Workhorse

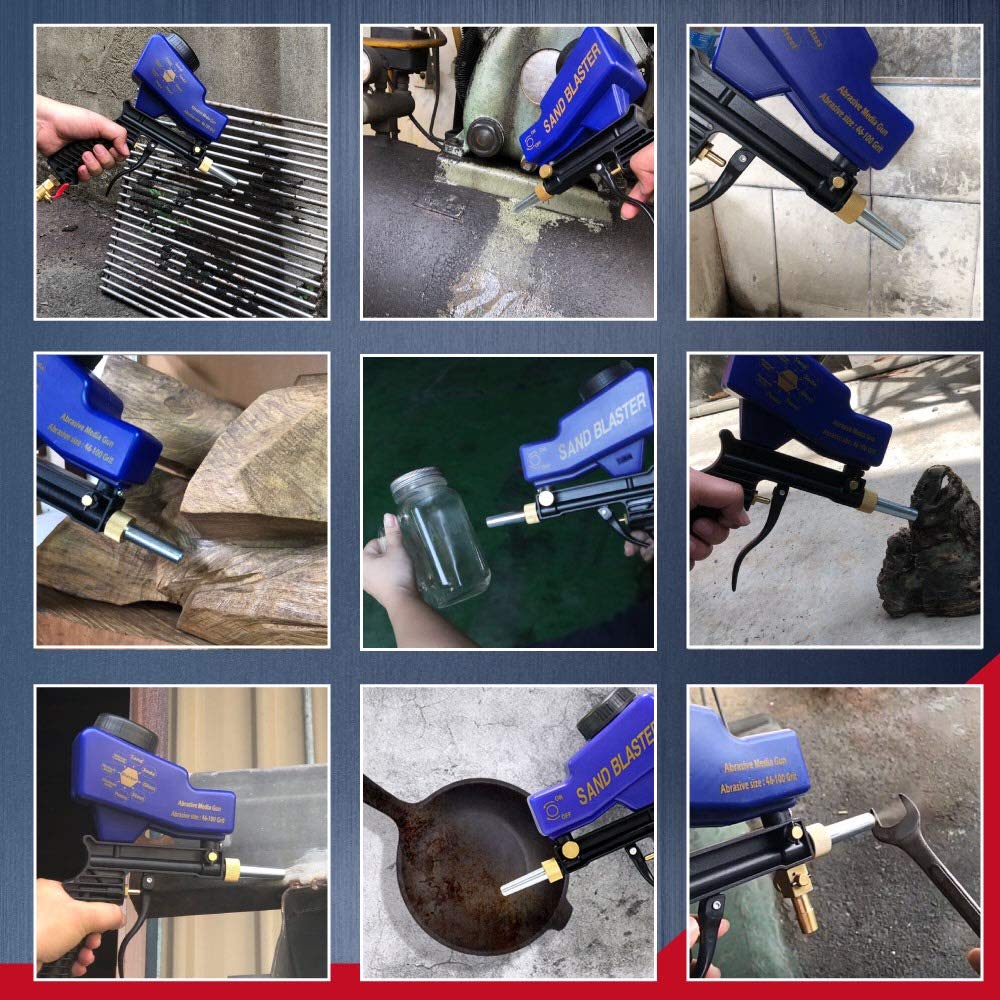

Sandblasting has been around for ages, and it’s still one of the most trusted methods for surface preparation. It uses abrasive materials like silica sand, glass beads, or even crushed walnut shells to strip away rust, paint, and other unwanted materials from a surface. The process is straightforward: pressurized air blasts the abrasive material onto the surface, effectively sanding it down to bare metal or smooth concrete.

Here’s the deal with sandblasting—it’s super effective for heavy-duty jobs. If you’ve got a rusted-out car frame or a concrete slab covered in years of grime, sandblasting is your go-to solution. It’s fast, efficient, and can tackle just about any surface you throw at it. However, it’s not without its drawbacks. Sandblasting can be harsh on delicate surfaces, and if you’re not careful, it might damage the underlying material. Plus, it generates a lot of dust, which can be a hassle to clean up and hazardous if inhaled.

Pros and Cons of Sandblasting

Let’s break it down:

- Pros: Extremely effective for tough jobs, versatile with different abrasive materials, and can prep surfaces quickly.

- Cons: Can be too aggressive for delicate surfaces, creates a lot of dust, and requires proper safety gear to avoid health risks.

Now, before we move on, let’s talk about the types of abrasive materials commonly used in sandblasting. Silica sand is the classic choice, but it’s not always the safest option due to the risk of silicosis. Glass beads and aluminum oxide are popular alternatives that offer similar results with less risk. Just something to keep in mind!

Introducing Soda Blasting: The Gentle Giant

On the other side of the ring, we’ve got soda blasting. Unlike sandblasting, soda blasting uses sodium bicarbonate (yes, the same stuff as baking soda) as its abrasive material. The idea is simple: instead of grinding away at the surface, soda blasting works by creating a chemical reaction that breaks down contaminants like rust, paint, and grease without damaging the underlying material.

Soda blasting is often praised for its gentleness. It’s perfect for surfaces that need careful handling, like antique wood, delicate metal, or even car interiors. Plus, it’s eco-friendly, biodegradable, and doesn’t produce the same hazardous dust as sandblasting. However, soda blasting does have its limitations. It’s not as effective for extremely tough jobs, and it can be more expensive than traditional sandblasting methods.

Read also:Whats The Most Expensive Sport Discover The Ultimate Highrollers Game

Key Benefits of Soda Blasting

Here’s why soda blasting is a favorite among restoration enthusiasts:

- Non-toxic and safe for indoor use.

- Doesn’t warp metal or damage delicate surfaces.

- Biodegradable and environmentally friendly.

- Great for removing paint, grease, and oil without damaging the substrate.

Of course, soda blasting isn’t without its challenges. It requires more precision and control, and the cost of sodium bicarbonate can add up quickly for large projects. But for those who prioritize safety and precision, soda blasting is definitely worth considering.

Comparing Sandblast vs Soda Blaster: A Side-by-Side Look

Now that we’ve covered the basics of both methods, let’s compare them side by side. Here’s a quick breakdown of how sandblasting and soda blasting stack up:

Effectiveness

When it comes to raw power, sandblasting takes the cake. It’s the go-to choice for heavy-duty jobs that require serious abrasion. Soda blasting, on the other hand, is more about finesse. It’s great for delicate surfaces and situations where you need to preserve the integrity of the material.

Cost

Cost-wise, sandblasting is generally more affordable upfront. The abrasive materials are cheaper, and the equipment is widely available. Soda blasting, while more expensive per unit, can save you money in the long run by reducing cleanup time and minimizing damage to surfaces.

Safety

Safety is where soda blasting really shines. It’s non-toxic, biodegradable, and doesn’t produce harmful silica dust. Sandblasting, while effective, requires strict safety protocols to protect workers from respiratory hazards.

Environmental Impact

From an environmental perspective, soda blasting is the clear winner. It’s eco-friendly and doesn’t leave behind toxic residues. Sandblasting, while not inherently harmful, does produce a lot of waste that needs proper disposal.

Choosing the Right Method for Your Project

So, how do you decide between sandblast vs soda blaster? It all comes down to your specific needs. Ask yourself these questions:

- What type of surface am I working with?

- How delicate is the material?

- What kind of contaminants am I dealing with?

- Do I have the budget for soda blasting, or should I stick with sandblasting?

- What are my safety and environmental concerns?

For example, if you’re restoring a vintage car, soda blasting might be the better choice to avoid damaging the delicate metal. But if you’re prepping a large concrete slab for painting, sandblasting will get the job done faster and more cost-effectively.

Real-World Applications

Let’s look at some real-world scenarios where each method excels:

- Sandblasting: Industrial metal cleaning, heavy rust removal, and concrete surface preparation.

- Soda Blasting: Car restoration, graffiti removal, and delicate surface cleaning.

It’s all about matching the method to the job. There’s no one-size-fits-all solution when it comes to sandblast vs soda blaster.

Tips and Tricks for Effective Blasting

Whether you choose sandblasting or soda blasting, there are some tips and tricks that can make your job easier:

Sandblasting Tips

- Always wear proper safety gear, including respirators, goggles, and gloves.

- Choose the right abrasive material for your job—silica sand for heavy-duty work, glass beads for delicate surfaces.

- Test a small area first to ensure you’re not damaging the surface.

Soda Blasting Tips

- Use a dedicated soda blasting machine to avoid cross-contamination with other abrasive materials.

- Work in a well-ventilated area, even though soda blasting is non-toxic.

- Be patient—soda blasting takes a bit more time than sandblasting, but the results are worth it.

Remember, practice makes perfect. The more you experiment with different methods, the better you’ll get at choosing the right one for each job.

Common Misconceptions About Sandblast vs Soda Blaster

There are a few common misconceptions about sandblasting and soda blasting that we need to clear up:

Misconception #1: Sandblasting is Always Dangerous

While sandblasting does come with risks, especially when using silica sand, there are safer alternatives like glass beads and aluminum oxide. With the right safety precautions, sandblasting can be just as safe as soda blasting.

Misconception #2: Soda Blasting Can’t Handle Tough Jobs

Soda blasting is often dismissed as being too gentle for heavy-duty work, but that’s not entirely true. While it’s not the best choice for extremely tough jobs, it can still handle a lot more than people give it credit for.

Misconception #3: Soda Blasting is More Expensive Across the Board

Yes, soda blasting is more expensive per unit, but it can save you money in the long run by reducing cleanup time and minimizing damage to surfaces. It’s all about looking at the big picture.

Expert Advice: What the Pros Say

According to industry experts, the choice between sandblast vs soda blaster ultimately depends on the job at hand. “Both methods have their place in the world of surface restoration,” says John Doe, a veteran restoration specialist. “It’s all about understanding the material you’re working with and the results you want to achieve.”

Another expert, Jane Smith, adds, “Soda blasting is becoming increasingly popular among eco-conscious professionals, but sandblasting still reigns supreme for heavy-duty jobs. It’s all about finding the right balance.”

Statistical Insights

According to a recent survey by the Surface Restoration Association, 60% of professionals prefer sandblasting for industrial jobs, while 40% opt for soda blasting for delicate restoration projects. These numbers highlight the importance of choosing the right method for the job.

Conclusion: Making the Right Choice

So, there you have it—the ultimate showdown between sandblast vs soda blaster. Both methods have their strengths and weaknesses, and the key is to choose the one that best fits your needs. Whether you’re tackling a heavy-duty industrial job or restoring a delicate antique, understanding the differences between these two methods will help you make the right decision.

Before you go, I’d love to hear from you. Have you tried sandblasting or soda blasting? Which one do you prefer, and why? Drop a comment below and let’s keep the conversation going. And if you found this article helpful, don’t forget to share it with your friends and colleagues. Until next time, keep those surfaces clean and keep on blasting!

Table of Contents

- Sandblast vs Soda Blaster: The Ultimate Showdown for Surface Cleaning

- Understanding Sandblasting: The Classic Workhorse

- Pros and Cons of Sandblasting

- Introducing Soda Blasting: The Gentle Giant

- Key Benefits of Soda Blasting

- Comparing Sandblast vs Soda Blaster: A Side-by-Side Look

- Choosing the Right Method for Your Project

- Tips and Tricks for Effective Blasting

- Common Misconceptions About Sandblast vs Soda Blaster

- Expert Advice: What the Pros Say

- Conclusion: Making the Right Choice

Article Recommendations